In the world of food and beverage processing, the ability to capture and retain the authentic flavours of raw materials is crucial. Traditionally, many flavour extraction technologies focus solely on capturing aromas from clear liquids, which often results in an incomplete or diluted representation of the original material. This is where Flavourtech’s Integrated Extraction System (IES) stands apart as an industry-leading solution.

The second generation, improved IES is the only system that incorporates the globally recognised Spinning Cone Column (SCC) for flavour extraction from slurries, purees, juices, and extracts. Unlike other flavour extraction technologies that work only with clear liquids, the IES ensures the preservation of the true essence of the raw material, making it an ideal and sought after innovation in the food and beverage industries.

The Integrated Extraction System (IES) – Second Generation

The IES is designed to address the limitations of conventional flavour extraction technologies, offering a unique, efficient, and high-quality approach to flavour extraction. Features of the system include:

1. Utilisation of the spinning cone column and the slurry preparation module: The Slurry Preparation Module accepts roasted coffee beans; tea leaves or other plant material and employs specialised milling techniques to minimise flavour loss. It prepares and maintains a uniform slurry as the feed stream for the SCC ensuring flavour recovery is as consistent and efficient as possible.

The SCC is Flavourtech’s proprietary and industry recognised technology that allows for superior aroma recovery. Unlike traditional methods that extract flavours from clear liquids, the SCC can process liquids containing suspended solids, ensuring a more complete and accurate representation of the original material’s flavour profile. The system operates under vacuum by spinning thin films of liquid, and slurries or purees over rotating cones, allowing the effective capture of delicate volatile compounds without excessive heat exposure. This process ensures that the flavours retained are a true representation of the raw material, as opposed to a diluted or modified version.

With coffee and tea in particular, the SCC performs the dual role of flavour and soluble solids extraction, that is, brewing the tea or coffee at the same time as recovering the aroma. This means that volatile flavour compounds are captured as soon as they are released and are then stored thus avoiding potential damage by subsequent processing.

2. Extraction of roast and ground coffee flavours: One of the biggest challenges in the coffee industry is retaining the rich, complex aroma of roast and ground coffee beans. Conventional extraction methods result in significant flavour loss, as the volatile compounds responsible for coffee’s distinctive aroma are lost to the external environment during processing. The IES, with its SCC technology, ensures that the essential roast and ground coffee flavours are extracted directly from the beans before they are lost in the extraction process.

3. Single estate tea flavour retention: The IES is particularly valuable for the tea industry, where preserving the distinct character of single estate teas is essential. Instead of relying on generic tea extracts that lose much of their delicate flavours, the IES captures the true essence of the tea leaves, resulting in a more authentic and high-quality product. In particular, the extracted flavour is heavily weighted in light, ‘front-end’ compounds, which are generally lost in other flavour extraction techniques, like packed column or bubble cap distillation technologies.

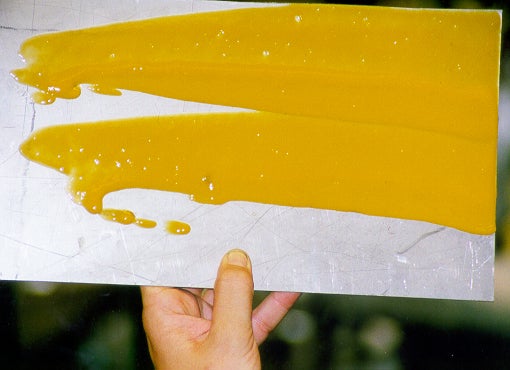

4. Enhanced flavour extraction from fruit, vegetables, and botanicals: The ability to extract flavours from not just the liquid components but also the solid materials in fruit, vegetables, and botanicals is a major advantage. For example, mango juice alone does not fully represent the richness of the fruit’s aroma, whereas extracting flavours from mango puree—which includes both the solids and the juice—results in a more authentic taste experience.

5. Gentle processing for higher quality: Unlike conventional thermal processing methods that can degrade delicate flavour compounds, the IES operates under gentle conditions (using lower operating temperatures under vacuum and residence times of less than 30 seconds), preserving the natural aromas and ensuring a fresher, more authentic taste in the final product.

6. Continuous processing for maximum efficiency: The IES is designed for continuous processing, making it highly efficient and suitable for large-scale production. This enhances productivity and reduces operational costs while maintaining superior flavour integrity.

Comparing the IES to conventional flavour extraction technologies

Conventional flavour extraction systems are designed to work exclusively with clear liquids, limiting their ability to preserve the full spectrum of flavour compounds present in raw materials. Below is a comparison of the IES against conventional distillation technologies:

| Feature | Integrated Extraction System (IES) | Conventional distillation technologies |

| Raw Material Processed | Slurries, purees, juices, and extracts | Clear liquids only |

| Key Technology | Spinning Cone Column (SCC) | Standard aroma stripping techniques |

| Coffee Flavour Retention | Captures aroma prior to extraction, preventing loss/damage to key volatiles | Captures aroma from liquid extracts only, leading to loss of key volatiles |

| Tea Flavour Retention | Preserves single estate tea characteristics | Uses generic extracts, losing regional uniqueness |

| Fruit & Vegetable Flavours | Captures flavours from puree, ensuring a richer, more complete profile | Captures flavours from clear juice only, missing solids-derived flavours |

| Heat Sensitivity | Gentle processing to retain delicate aromas | High-temperature processing that can degrade flavours |

| Processing Efficiency | Continuous, high-efficiency production | Batch processing, lower efficiency |

Case Study: Coffee Flavour Extraction

To understand the significance of the SCC, consider the example of coffee processing. In traditional coffee extraction systems, coffee flavour is extracted from the brewed liquid, which has already lost many of the volatile compounds during the high temperature brewing process. This results in an incomplete representation of the original roasted bean aroma. With the IES, however, the flavours are captured directly from the roast and ground beans in a closed system, that simultaneously performs the brewing process. This ensures that the final product retains an authentic and complex coffee profile whether it be destined for use as a natural coffee flavour, extract, concentrate or powder.

Case Study: Mango Flavour Extraction

A similar principle applies to mango processing. In conventional systems, the aroma is typically extracted from mango juice, missing the essential compounds found in the fruit’s pulp and skin. The IES, by contrast, processes mango puree, incorporating both juice and solids, leading to a more complete and true-to-nature mango flavour.

Flavourtech’s second generation IES represents a shift in flavour extraction technology. By utilising the industry-recognised SCC, it offers distinct advantages over traditional aroma extraction methods, ensuring that the flavours retained are the truest representation of the original raw material. Whether in coffee, tea, fruit, vegetable, or botanical processing, the IES stands as the ultimate solution for achieving superior flavour quality, efficiency, and authenticity.

For manufacturers looking to elevate and differentiate their product offerings while capturing the purest flavours possible, Flavourtech’s IES is the clear choice.

For more information, download our brochure on the Integrated Extraction System.