Thin-film spinning cone technologies are making waves in the F&B market; market leaders are already adopting them to aid dealcoholisation, aroma recovery, extraction and concentration.

Tim Birks is an expert in dealcoholisation technologies at Flavourtech. The company, established over 30 years ago in Australia as pioneers in dealcoholisation, developed the Spinning Cone Column (SCC) technology now seen as the industry standard for removing alcohol from wine. Here, Tim answers questions regarding both the Spinning Cone and Resin Adsorbing Column (RAC) technologies and how they are helping wineries around the world produce award-winning low and zero alcohol wines. He also hints at upcoming innovations in this space with the mention of the next generation of Flavourtech dealcoholisation systems.

1. What is the SCC?

The SCC was developed and commercialised in the 1980’s by Australian company, Flavourtech Pty Ltd. The technology uses steam under vacuum at low temperatures to gently separate volatile compounds, like aroma and alcohol, from liquids, purees and slurries. It has many applications but is considered by many as the gold standard for removing alcohol from wine, beer and other alcoholic beverages.

2. How does the SCC work?

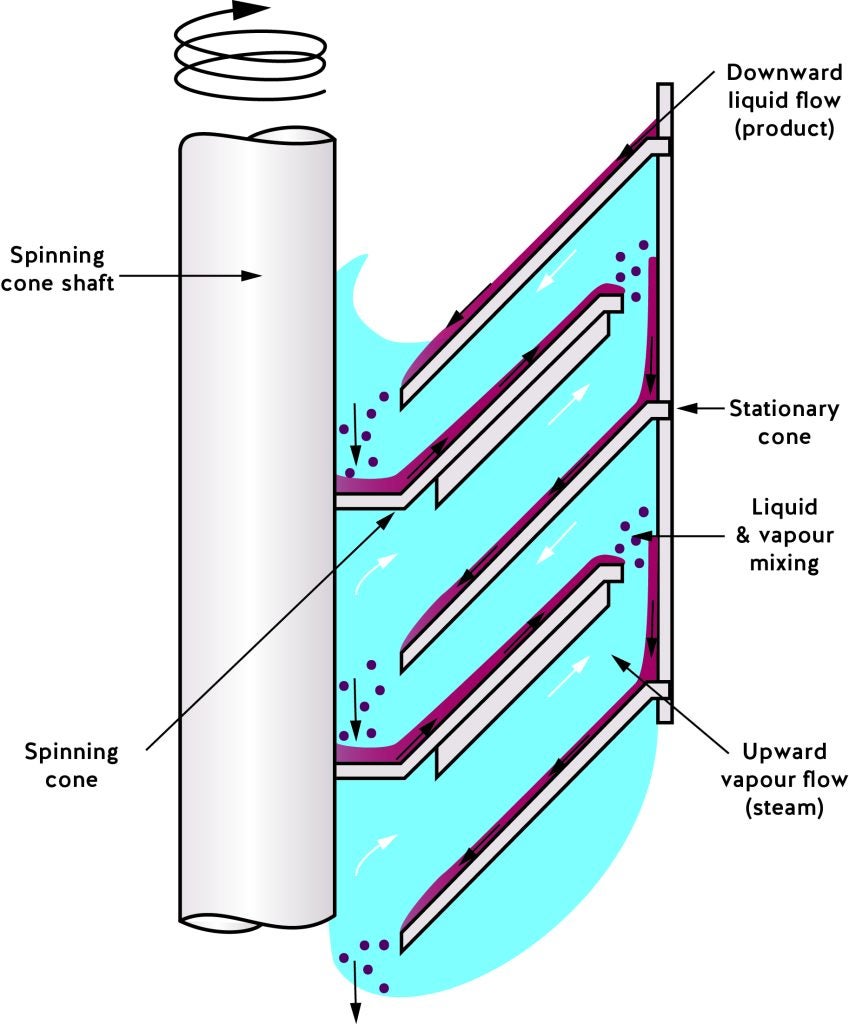

The SCC is a vertical stainless-steel distillation vessel containing a rotating shaft and a series of rotating and stationary cones.

Step 1

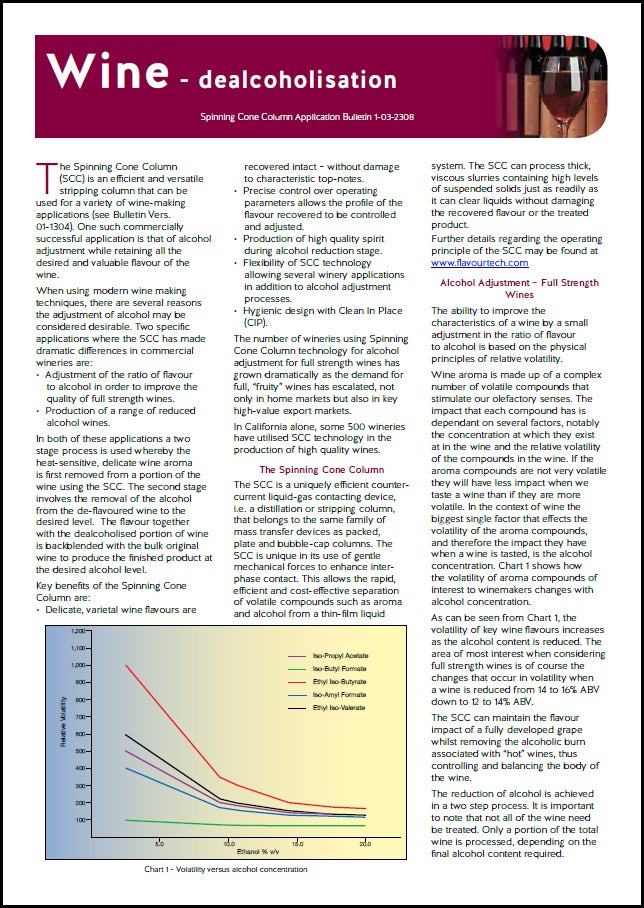

As depicted in Figure 1, full-strength wine is introduced at the top of the vessel, flowing down via gravity onto the upper surface of the first stationary cone as a thin film (approximately 1mm in thickness) before flowing down onto the first rotating cone. Through centrifugal force, it is sent to the next stationary cone. The wine continues moving down the column in this manner, cone by cone, before being pumped out at the bottom of the vessel. Meanwhile, stripping steam (which may be generated from the wine itself), is introduced at the base of the vessel and flows upwards taking the wine’s volatile aroma compounds with it. The stripped volatiles are condensed into a concentrated alcoholic liquid and stored for re-addition to the wine at a later stage.

Step 2

The aroma-stripped wine is passed through the SCC a second time to remove the bulk of the alcohol. Alcohol levels in the wine exiting the SCC will typically be between 0.05% and 0.1% abv and can be adjusted depending on requirements.

Step 3

The dealcoholised wine and (alcoholic) aroma fraction are combined to achieve a low alcohol wine (as low as <0.5% abv) with delicate varietal flavour. Meanwhile, the alcohol that was removed from the wine is in the form of a high-quality spirit that can be sold or used in other applications.

3. What temperature does the SCC process wine at?

A first pass gently removes the wine’s aroma at temperatures of approximately 30oC while a second pass dealcoholises the aroma stripped wine at temperatures of approximately 40oC.

4. How long is the residence time within the SCC?

The wine passes through the column in less than 30 seconds.

5. Are the valuable aromas from the original wine lost when dealcoholising with the SCC?

This combination of low operating temperatures with short residence times results in the wine’s fragile aroma compounds being preserved during SCC processing. The formation of heat-derived flavours and colour changes in the wine being dealcoholised are also avoided by limiting these two variables. The end result is a high-quality reduced alcohol wine that that is true in varietal aroma to the original wine itself.

6. What concentration is the alcohol removed by the SCC?

This depends on the alcohol concentration in the feed wine. However, many wineries are targeting 65-75%v/v which Flavourtech makes possible using a relatively new design innovation called ‘alcohol reconcentration’.

More recently, Flavourtech has continued developing the alcohol reconcentration concept and expect to install the first of our next generation dealcoholisation systems later this year which, in addition to a number of other exciting upgrades, will allow alcohol output concentrations of above 90%v/v.

7. Is anything additional added to the wine during SCC processing (for example water)?

No, nothing is introduced to the wine during SCC processing. Even the steam used to strip volatile aroma compounds and alcohol is generated from the wine itself. This option is called ‘reinjection’ in which a portion of the wine is gently heated under vacuum to create steam, meaning that no external water is added during processing.

8. What if I would like to create zero alcohol wine at <0.05% abv?

While production of wine at <0.5% abv is handled solely by the SCC, initially zero alcohol products at <0.05% abv could only be created by adding back part of the alcoholic aroma fraction recovered by the SCC. Flavourtech has therefore recently developed the Resin Adsorbing Column. The RAC, when used in conjunction with the SCC, allows the total volume of the wine’s aroma to be incorporated into the final product while still achieving the <0.05% abv target. The process results in a high quality zero alcohol ‘wine product’ without the need to add external flavours.

9. How does the RAC work?

The wine’s alcoholic SCC aroma is passed through the RAC which contains a specially selected resin that ‘traps’ the aroma compounds (by adsorption) while allowing ethyl alcohol and water to pass through and be collected as a neutral, clean alcoholic by-product. After a water rinse, the wine’s aroma compounds are desorbed from the resin (without the use of organic solvents) resulting in an aqueous based aroma that can be added back to the delacoholised wine to create a flavoursome zero alcohol product at <0.05% abv.

10. What if I am a small winery wanting to enter the reduced alcohol wine market?

In 2022, Flavourtech released the SCC100-W, a small-scale SCC for dealcoholising wine. With an average throughput of approximately 25L/hr when producing 0.05%v/v wine products, this smaller model is perfect for smaller wineries wanting to enter the low or zero alcohol wine market or larger wineries wanting to perform R&D on reduced alcohol wines.

Previously, the smallest SCC model was the SCC1,000-W which dealcoholises wine at a throughput of 100-150L/hr.

For larger production runs, the SCC10,000-W with a throughput of 1,000-1,500L/hr of wine is available with the option of installing multiple columns on the same skid for even larger scale production of reduced alcohol wine.

11. Can I see how these technologies work with my wine?

Flavourtech has demonstration facilities around the world for clients’ dealcoholisation trials. Visit their pilot plant facilities in Australia, the United States or their brand-new facility at Wageningen University’s Food Valley in the Netherlands. Portable rental units are also available for wineries wanting to conduct more extensive product development work on site.

12. Is the SCC in commercial operation for the production of reduced alcohol wines?

Yes! For over 30 years, the SCC has been the preferred method around the world for the dealcoholisation of wine. It was developed specifically for this application in one of Australia’s largest grape growing regions and has received numerous upgrades over the years to keep it at the forefront of dealcoholisation techniques. The SCC is used throughout the wine industry for alcohol adjustment of full-strength wines, production of mid- and low-strength wines and, more recently, zero alcohol wines. In fact, zero alcohol wines produced using the SCC have recently been awarded “Overall Judges’ Wine of Show” at the 2023 Mid-Low-No Alcohol Awards in Sydney and 8 of the 9 gold medals at the 2023 World Alcohol-Free Awards demonstrating their exceptional flavour profiles.

Further details: For more information on Flavourtech’s Spinning Cone Column for dealcoholisation of wine, please download the whitepaper below or contact their team at sales@flavourtech.com.