FlexMill Production

FREWITT, world leader in powder size reduction technologies, presents FlexMill, an innovative technology combining multiple, milling processes in a single, milling platform dedicated to the pharmaceutical, chemical and food products industries.

FREWITT, world leader in powder size reduction technologies, presents FlexMill, an innovative technology combining multiple, milling processes in a single, milling platform dedicated to the pharmaceutical, chemical and food products industries.

Modularity

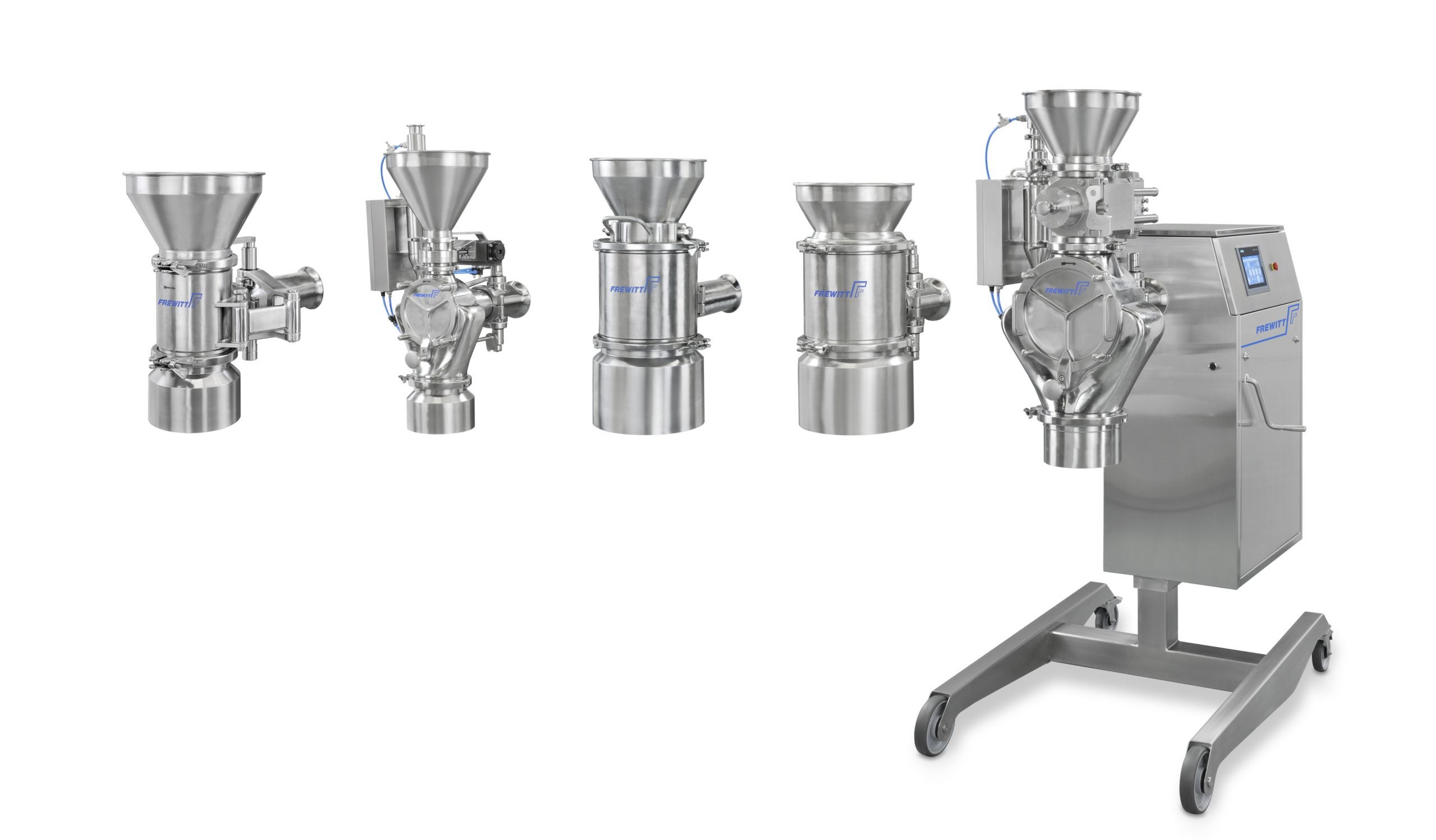

A distinctly avant-garde, modular concept: FlexMill allows you to alternate, depending on your production requirements, between 5 milling heads for size-specific crushing, fine grinding, de-agglomeration, or controlled sifting.

Flexibility

Incomparable versatility: FlexMill allows you to adapt your milling platform easily and quickly, to suit your current or future production requirements, regardless of your manufacturing environment or production site.

Performance

Enhanced by a factor of 5: FlexMill proves its capabilities with the same degree of flexibility across the entire range of your processing needs, from small batch to large-scale production.

Savings

Enhanced return on investment and lower cost of ownership: FlexMill integrates three milling processes into a single platform, allowing you to use up to 5 different heads and reduce investment costs by 70%.

Three processes – five milling heads – one system

This innovative system is a unique multi-process platform. Unequalled flexibility and extraordinary performance allow for significant savings. Owing to a design enabling the use of up to five different interchangeable milling heads on the same base module, FlexMill permits conical sieve milling, hammer milling, and controlled sifting operations – all with a sole compact platform.

New features and advantages

- Three processes > five heads > one platform

- Five milling heads, easily interchangeable on a single Tri-Clamp flange

- Enhanced milling capacity, from small batches to high volume production jobs with integrated scale-up factors

- Auto-detection of milling heads and auto-adjustment of associated speed ranges

- Intuitive colour touchscreen-based multifunction user interface

- Available in a mobile version with integrated lifting system for ATEX zones 1 and 21

- Continuous monitoring of operation status with integrated diagnostics

- Integration and management of production formulas in the machine

- Real-time monitoring and reporting of process parameters

- CFR Part 11 functions integrated in the control module

- Available for products with MIE >1 mJ without inerting process