Flavourtech Releases its Small SCC100 Aroma Recovery Unit

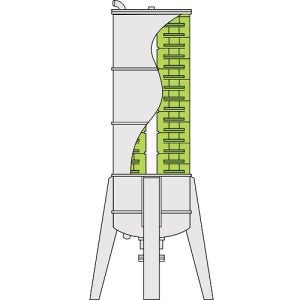

Flavourtech is proud to announce the SCC100, which is the newest member of the Spinning Cone Column (SCC) family. The SCC100 is the smaller sibling to the SCC1,000 and SCC10,000, which are used around the world for aroma recovery, flavour management and extraction from liquids, purees and, uniquely, slurries of suspended solids. This continuous, automated processing technology allows food and beverage manufacturers to produce high-quality products that possess the natural aroma of the original raw material.

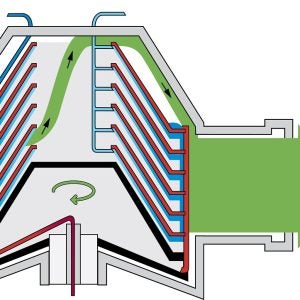

The technology’s unique thin-film design is responsible for the short residence time and low operating temperature conditions that are advantageous when compared to other distillation techniques. These conditions result in a lower thermal impact on the raw material, producing higher quality products that consumers prefer.

Enter the SCC100. Flavourtech customers have for some time requested a pilot-scale SCC to assist them with research and development (R&D) work for flavour recovery applications. The new SCC100 has a throughput of 25 to 115l/h and is ideal for use in the laboratory, pilot plant or even small production runs. The compact system has been designed with an easy-to-use touch screen, lockable castors and is quickly assembled, operated and maintained by the user.

The SCC100 is capable of processing liquid products such as extracts, juices and dairy products and is able to perform such tasks as:

- Aroma recovery from coffee and tea extracts

- Aroma recovery from botanical extracts

- Aroma capture from fruit and vegetable juices

- Aqueous aroma re-concentration

In fact, by adjusting certain operating conditions, it is possible to achieve multiple flavour profiles from the same raw material and assist customers with their product development needs.

One popular SCC application is aroma capture from lemon juice, whereby this distinctive and highly desired aroma is gently stripped from the juice as an aqueous natural flavour stream. With the SCC, aroma recovery is performed quickly and gently so as not to damage existing flavours or add unwanted ‘burnt’ flavours. The resulting flavour stream can then be used in food manufacturing where the natural lemon flavour is required or as a ‘top-up’ to existing lemon juice products for an extra boost of flavour.

Speciality tea and coffee producers with requirements for smaller volumes of high-value products can also take advantage of the smaller SCC100. Such producers may wish to add back aroma recovered by the SCC100 to concentrated tea and coffee extracts, thus optimising flavour retention and creating a premium product for sale at a higher price point.

When asked regarding the development of the SCC100, Flavourtech’s general manager Leon Skaliotis commented that “shrinking down a highly sophisticated product to fit through a standard door was a challenge at first. It was our customers who requested this size and so we took on the challenge and I am absolutely delighted with the outcome. Our design, technical and engineering teams have worked tirelessly and produced a new model which we are all extremely proud of.”

“Our customers can now utilise an R&D-sized SCC for method development and then transfer over to the bigger SCC systems quickly and easily.”

Visit flavourtech.com/products/spinning-cone-column/ to find out more.