TOMRA Sorting Food specialises in the manufacture of sensor-based sorting machines and post-harvest solutions for the food industry.

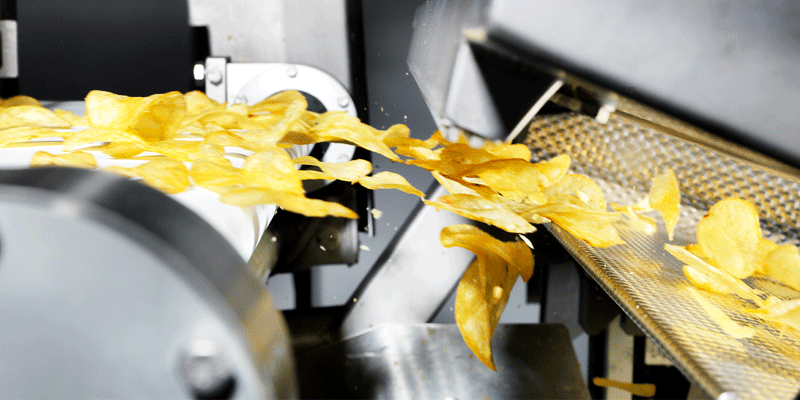

The machines are designed for processing a wide range of products, including fruit and dried fruit, seeds, meat, poultry, gummies, nuts, potatoes, seafood, vegetables and tobacco.

The company’s innovative sorting technologies utilise advanced peeling, analysis and grading technologies to precisely sort products and optimise production flow.

Sorters for the food processing industry

TOMRA Sorting Food offers an efficient, high-capacity solution for sorting food products that assures consistently high-quality food.

The sensor-based sorting solutions are designed to boost processing capacity and availability, as well as quality and food safety. Their energy-efficient design helps optimise yield and recovery and reduce waste.

The Field Potato Sorting Machine (FPS) is a robust potato sorter that removes soil clods, stones and other foreign materials. Its unique vision system precisely separates unwanted materials, including glass, metal, rubber and plastic at high unloading speeds. It has applications with white, brown, yellow, red and purple varieties, as well as seed, processing and speciality potatoes.

The Genius™ Sorting Machine is an optical belt sorting machine that utilises multiple sorting technologies for a wide range of food products. The unit is designed to meet the stringent requirements of the food industry and individual food processors. It removes discoloured products and foreign materials to ensure high food quality consistently throughout its service life.

Benefits of TOMRA’s food sorting machines include:

- An increased processing capacity

- An increased profit and yield

- Lower labour costs

- Consistent high quality food and safety

- Ease of use and reliability

Peeling solutions for vegetables and fruit processing

TOMRA Sorting Food offers a wide range of peeling solutions for the removal of skin from vegetables and fruit, including potatoes, carrots, sweet potatoes, swedes, celery, red beets, peppers, pumpkins and chilli.

With more than 40 years of experience in potato and root vegetable peeling, TOMRA Sorting Food’s machines can handle between 1,000kg and 65,000kg of product an hour, catering to all production scales. Focus is placed on improving efficiency, yield and food quality, as well as reducing peel loss.

Benefits of TOMRA’s steam peeling equipment include:

- Highly consistent and quick peeling times for a wide range of vegetables

- Reduction of product waste with a precise peel

- High-performance solutions with real-time adjustment

- Low operating and maintenance costs

- High yield due to optimal steam supply and steam exhaust

Inspection solutions for the vegetable and meat industry

TOMRA specialises in inspection solutions with process analytics and in-line analysers.

The company has 10,000 food sorters installed worldwide and offers a support and service network.

The Blizzard Sorting Machine is a cost-effective unit for processing individually quick-frozen (IQF) vegetables and fruit. It provides consistent inspection abilities to ensure misshaped and discoloured products are removed, as well as unwanted foreign objects. The machine is also easy-to-use with its intuitive graphical interface.

The QV-P in-line analyser is designed to quickly identify muscle myopathy in chicken fillets, removing them from the manufacturing line to improve product quality. The machine utilises multi-spectral lights for processing at high speeds. It can also accurately grade chicken, reducing the need for labour-intensive manual checks.

About TOMRA

More than 8,000 food growers, packers and manufacturers worldwide have benefitted from TOMRA Sorting Foods’ sorting, peeling and inspection solutions. The company aims to improve its client’s returns, operational efficiency and food safety through the prevision of sophisticated, innovative technologies.

TOMRA Sorting Food is a member of the TOMRA Group. The company has installations is more than 80 markets, reaching revenues of Nkr7.4bn. The group focuses on providing innovative solutions within its Collection Solutions and Sorting Solutions business areas. TOMRA’s sorting solutions help increase the yield of produce by around 10%, which is the equivalent of 25,000 trucks of potatoes every year.

TOMRA Sorting Food operates centres of excellence, regional offices and production facilities within the US, Europe, South America, Asia, Africa and Australasia.