Precise Mixing Control Whether Your Tank is Full or Nearly Empty Variable

Frequency Drives (VFDs) change the RPM of an electric motor by altering the frequency and voltage, accurately controlling motor speed, can be used to great advantage when coupled with a mixer. Mixquip Side Entry Agitator with VFDs are used to maintain a consistent level of agitation within a vessel, even when pumping out or if the tank is only partially full. The VFD is often integrated with a level sensor to automatically control mixing intensity, irrespective of tank volumes. Variable mixers are also ideal where tanks are used for different products, requiring varying mixing profiles.

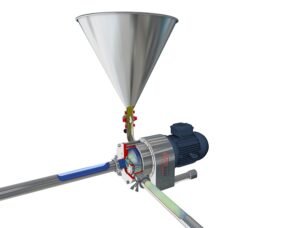

The Mixquip® Series 100 side entry agitator is an innovative approach to side entry mixing and incorporates state-of-the-art technology in agitator design and construction using composite materials resulting in improved efficiency, greater reduction in power consumption and lower shear. This series achieves as much as 65% greater blending capacity. They are cost-effective, energy-efficient and quiet in operation. The Mixquip® Series 100 Side Entry Agitator is ideally suited to fluids of medium-to-low viscosity where gentle low shear mixing or blending is required. Mixing or blending large volumes of liquid can also be achieved using Mixquip® Series 100 Side Entry Agitators that are smaller in size and more economical than other mixing arrangements that perform similar duties.

Advantages

Efficient mixing or blending to stored products

Mixquip’s Series 100 agitator has been carefully designed to maximise the efficiency of mixing. Our mixer options for the Series 100 include the most efficient designs available with the highest degree of mix in the shortest time whilst keeping energy consumption low.

Excellent liquid movement

Excellent liquid movement past in-tank heat transfer surfaces such as coils, tank jackets and spears that reduce ice build-up or fouling.

Prevents the settling or layering of stored products

Easy step-by-step removable seal

Easy step-by-step removable seal reducing downtime in servicing the seal. The seal is removed and replaced while holding the liquid in the tank resulting in no need for product transfer, no lost product, and a safer procedure.

Hygienic design

Hygienic design, by placing the mechanical seal within the wash zone of the tanks fitted with CIP.

Impeller options

Mixquip provides a wide range of impeller options with its own in-house designs to suit the exact requirements of a mixing process. The Superflo impeller incorporates technology designed using computational fluid dynamics providing the optimal results for low shear mixing with a powerful axial pumping stream.

Angular spacer housing

The angular spacer housing designed and developed by Mixquip provides flexibility by rotating the flange faces to provide optimum mixing conditions in various tank designs and configurations.

For more information, please follow the links on our profile.