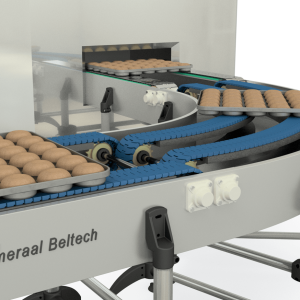

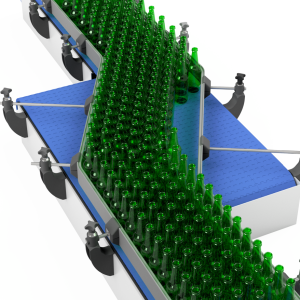

Ammeraal Beltech is a global belting company that supplies belting components, services and solutions for processing and conveying products.

Ammeraal Beltech is a member of AMMEGA, the combination of Ammeraal Beltech and Megadyne Group. The two strong brands and their respective business lines of conveying and power transmission will remain in the market and continue to build on the leading positions they have established.

Under the AMMEGA umbrella, the two brands will benefit from their synergies and will combine their knowledge, research and development activities, business systems and their people to enhance their level of customer service and technology.

All components and equipment in production lines are screened carefully to improve food safety and hygiene. As a leading producer of process and conveyor belts, particularly for the food industry, Ammeraal Beltech has made hygiene a focus of our business. Process requirements and product characteristics are always taken into account to achieve the most efficient solution.

Ammeraal Beltech has been setting the standard for many years with market-specific hygiene features. Continuing research and development has resulted in the design and production of a wide range of food safety solutions.

Antimicrobial conveyor belts

Ammeraal Beltech’s antimicrobial (AM) belting range uses non-migrating materials – a unique technology based on silver ions. The belts are proven safe for human contact and are effective against a broad spectrum of micro-organisms. Polyurethane Ropanyl homogenous and Nonex high-tech food grade blend are available with AM benefit particularly in light blue colour. AM technology is in the top ‘food-contact’ side as well as the bottom side providing full food safety protection.

- Reduce/bring down the counts of bacterial growth on the belt

- Enhance hygiene

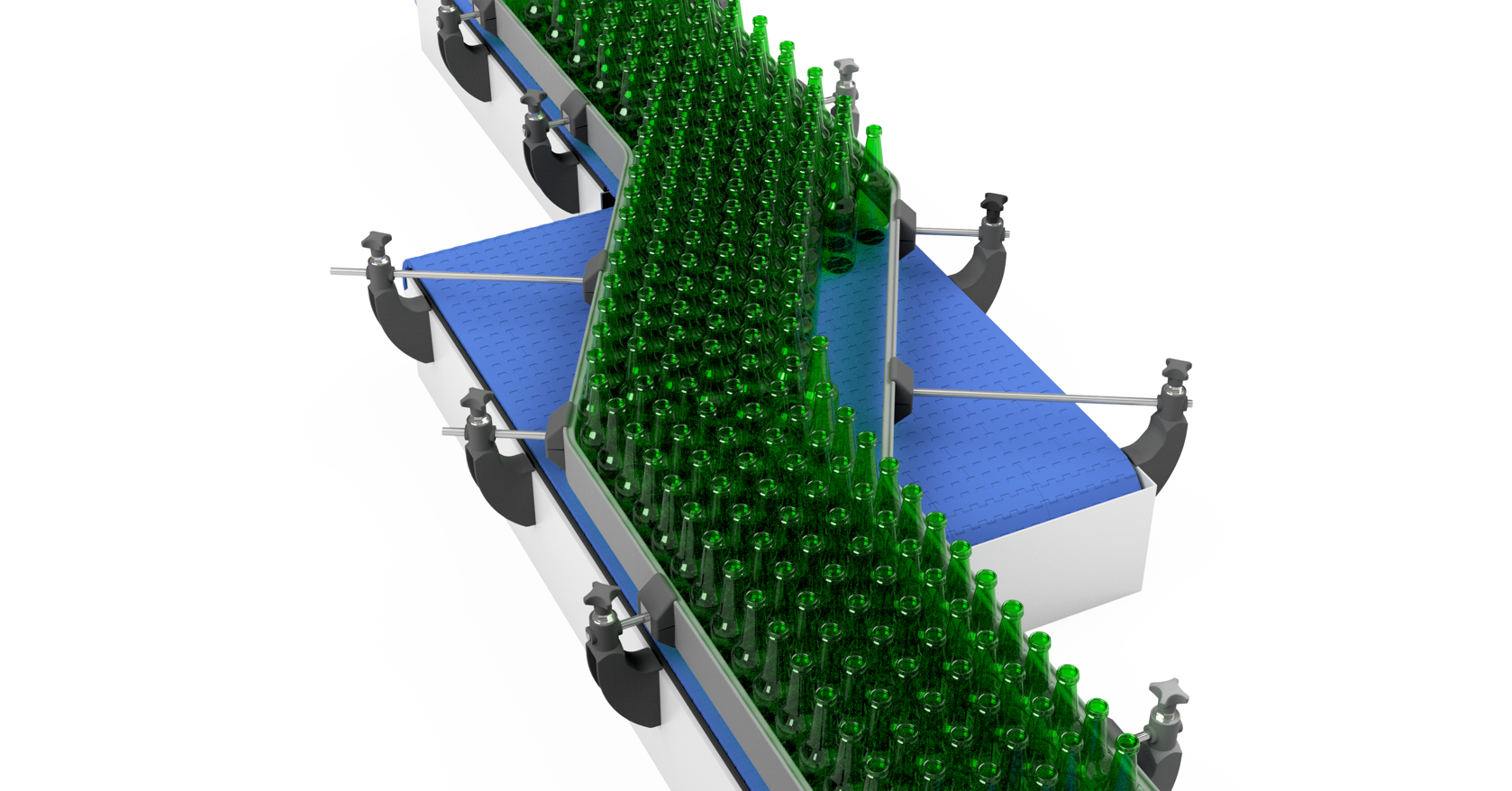

Light blue conveyor belts

Light blue belts from Ammeraal Beltech offer lasting support in meeting food safety standards. The blue colour of the belt makes it much easier to identify food product contamination.

- Improve hygiene

- Reduce chances of cross-contamination

- Less risk in product liability issues

- Easy to clean

- Reduce eye fatigue

Conveyor belts with contamination safeguards

KleenEdge® is so named to signify that the belt edge remains clean during use. This feature tackles contamination risks that may occur from belt edge wear, and the use of high-quality food-grade polyurethane foil technology enhances the overall condition of the food handling surfaces.

- Reduce contamination risks

- Non-Fray properties

- Extended belt life

- Easy to clean

- Low microbe and bacteria counts

- Resist long fibre pull out

- Avoid fibre contamination

Conveyor belts with footless flights

Ammeraal Beltech provides belts with high-frequency welded footless flights, ideally suited for applications where small drum diameters are used. The hygienic footless flights can be cleaned thoroughly, very easily and quickly thanks to the smooth and round transition from belt to carrier. A wide range of thermoplastic materials is available for any belt series also in light blue colour.

- Easy to clean

- Less cross contamination

- Lower bacteria counts

- Reduce cleaning time

- Improve visual aspects

Conveyor belts with closed belt edges

Belts with Amseal closed belt edges are protected against all kinds of external influences and circumstances because the Amseal edge protection completely seals the belt edge on all sides with a thermoplastic strip.

- Totally encapsulated belt

- Avoid fabric fibre contamination

- Easy to clean

- Less cross contamination

- Improved visual aspects

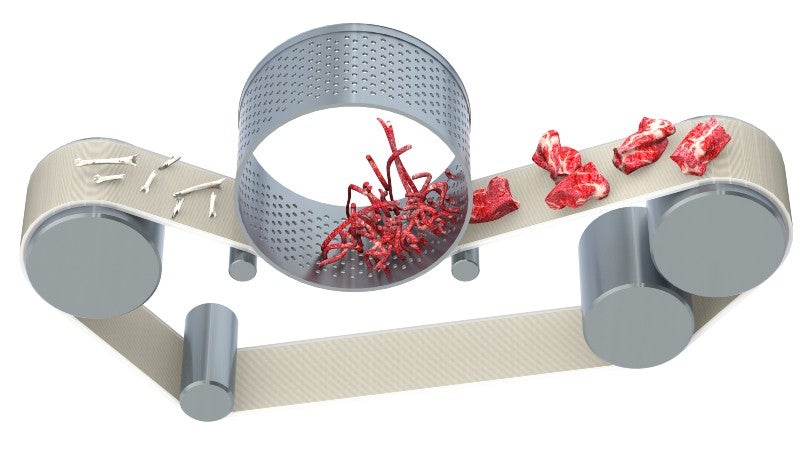

Modular belts for food processing

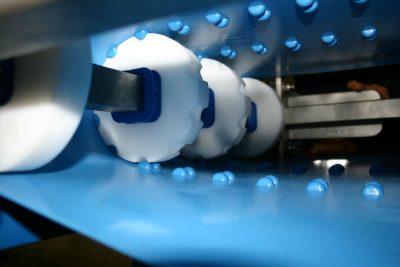

A new generation of modular belting has been specially developed for hygienic critical applications. With uni Single Link® belts, the entire link module is manufactured as a single component, thus avoiding the interconnecting joints and eliminating areas where cleaning is difficult and bacteria growth would normally re-start.

These new modular belts feature easy-to-clean surfaces, combined with the use of the latest food-safe, direct contact materials and a special surface manufacturing technology, all to achieve the highest possible food safety requirements.

Hygienic conveyor belts

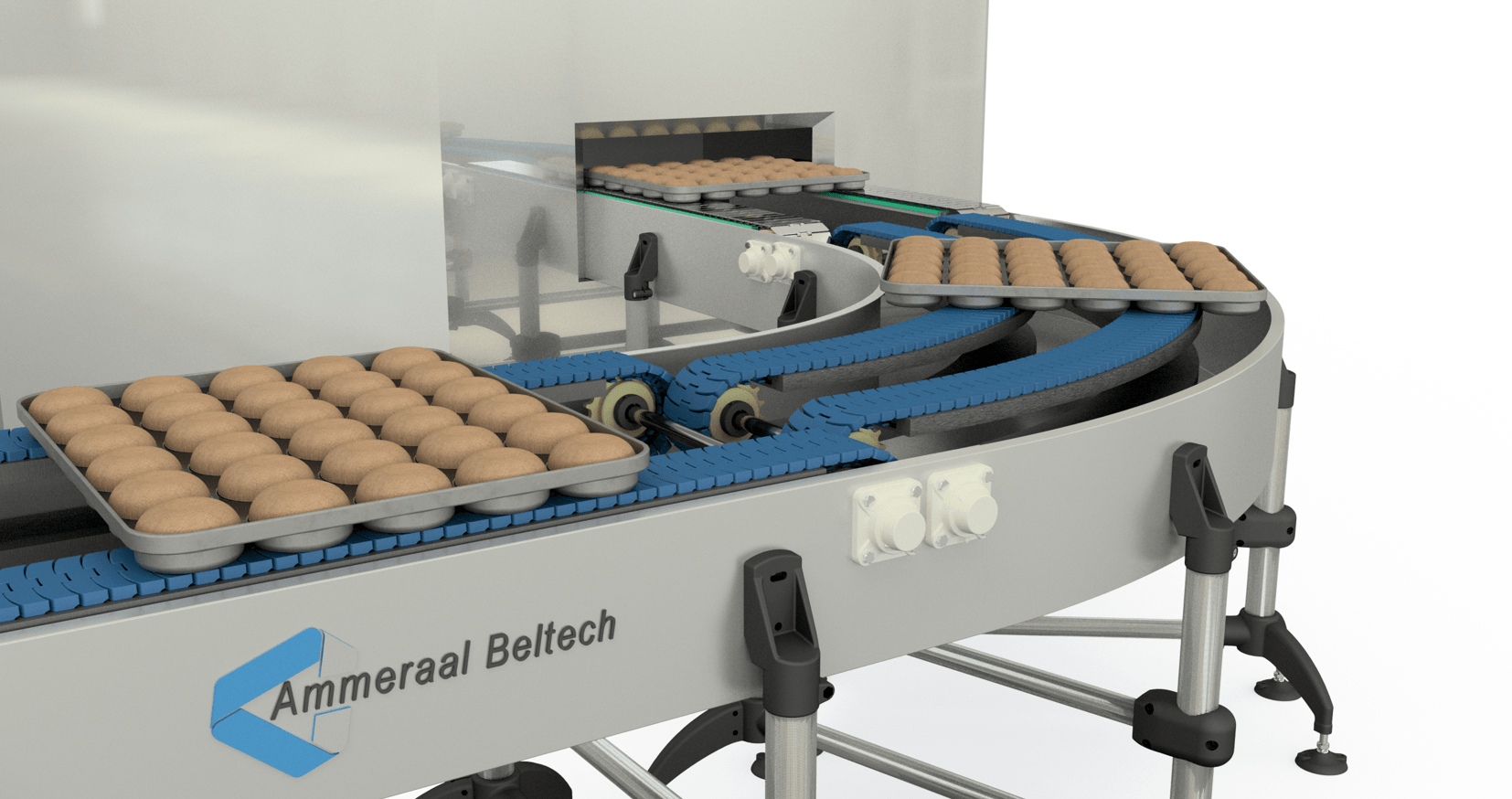

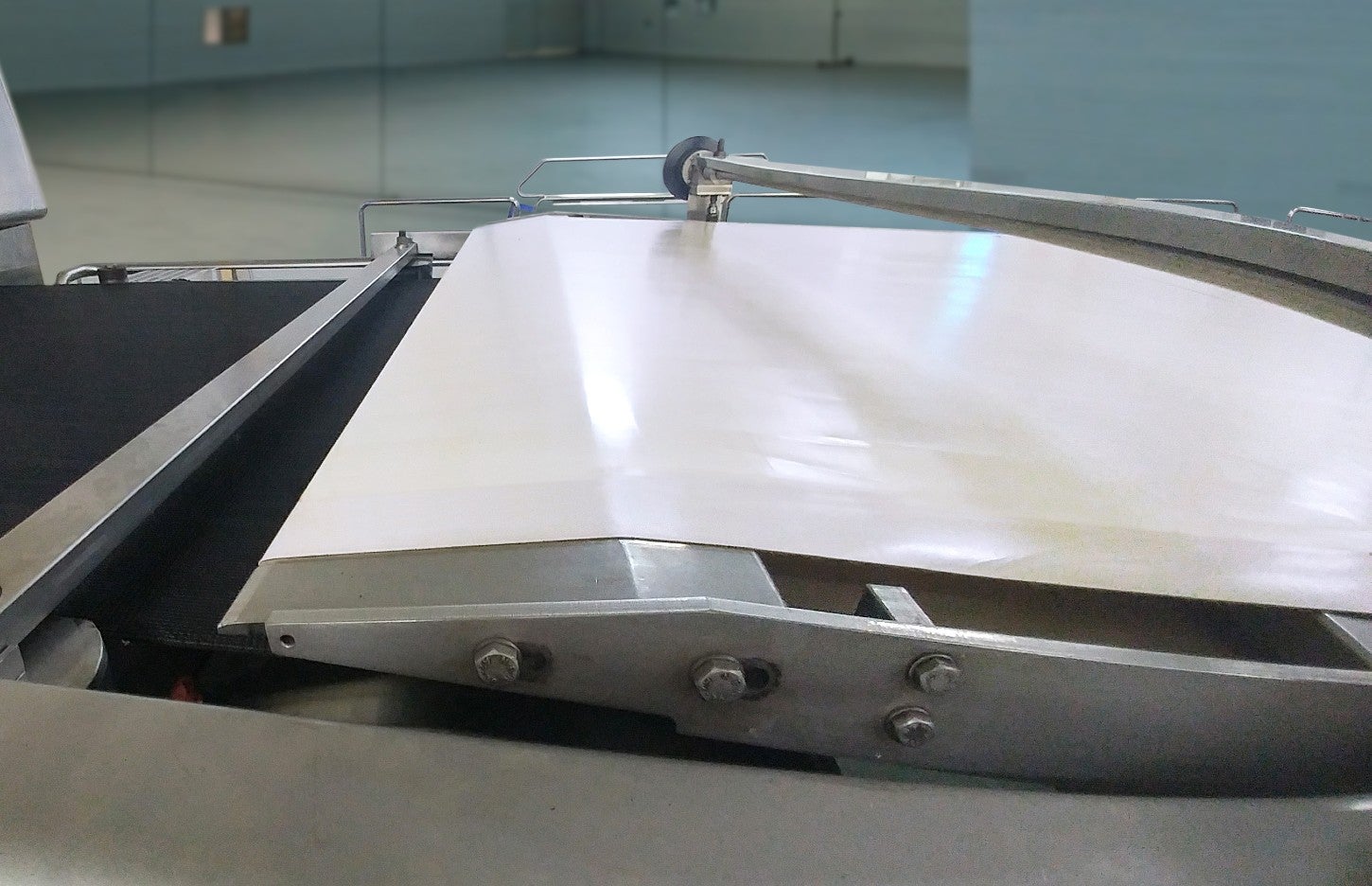

Soliflex PRO combines the benefits of standard fabric-based process and conveyor belts and modular belts into one unique new product. Soliflex PRO is a new range of homogeneous belts developed particularly for applications in the food industry.

Soliflex PRO belts are positive driven, hence without any slippage, and the unique design is self-tracking. This well-balanced concept allows for easy cleaning, reducing total cleaning costs in terms of time, water and cleaning agents.

- Totally out of any fibre contamination

- Easy and fast cleaning

- Non-stick properties

- Scraper friendly

Food conveyor belts according to food standards

Ammeraal Beltech belts meet international food standards:

- Assist in your HACCP programmes

- FDA, EU 1935/2004, EC 10/2011, USDA and NSF statements are available on demand, depending on belt type