Flavourtech Conducts Remote Plant Commissioning

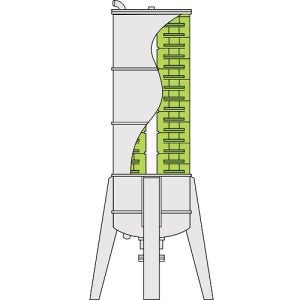

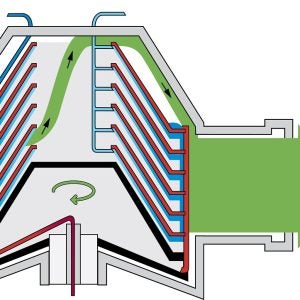

Photos above show the Spinning Cone Column (left) and Flavourtech automation engineer, David Hirst (right).

With international travel coming to a standstill during the Covid-19 pandemic, Flavourtech is continuing to support its global customers by conducting plant commissioning and end-user training sessions remotely.

Remote factory commissioning is now possible for many of Flavourtech’s technologies, such as the Spinning Cone Column and Centritherm® evaporator. Customers no longer have to wait for a Flavourtech engineer to be on site to have their installed equipment tested and move on to production.

Flavourtech also conducts Factory Acceptance Testing (FAT) in their own factory prior to packing and shipping plants to customers. As FAT is already complete, installation and remote start-up can then proceed on site with remote guidance from Flavourtech engineers.

Using audio-visual remote connections, Flavourtech engineers have successfully commissioned plants in New Zealand and the US, and are now preparing to conduct further remote commissionings in Russia, Belgium and the UK, all without leaving Flavourtech’s Australian head office.

Flavourtech is working closely with its customers to minimise interruptions to production and is developing best practices to enable businesses to access their engineer’s expertise remotely. With the assistance of the customer, audio-visual links and real-time data allow for commissioning to proceed with guaranteed operation and customer satisfaction.

Flavourtech is supporting various clients to ensure they have the production capacity on hand to proceed forward at speed when their markets return to normal post Covid-19. The company’s ability to remotely install and commission its unique process technologies is assisting food and beverage manufacturers to continue on with these plans and survive well into the future.

Contact Flavourtech via the enquiry form for further information on their Spinning Cone Column and Centritherm evaporator technologies.