Passion for Potato Chips

Rosenqvists Food Technologies has extensive knowledge of the potato as a raw material and how to design an effective process.

You have successfully submitted your enquiry. Someone from our company will respond ASAP

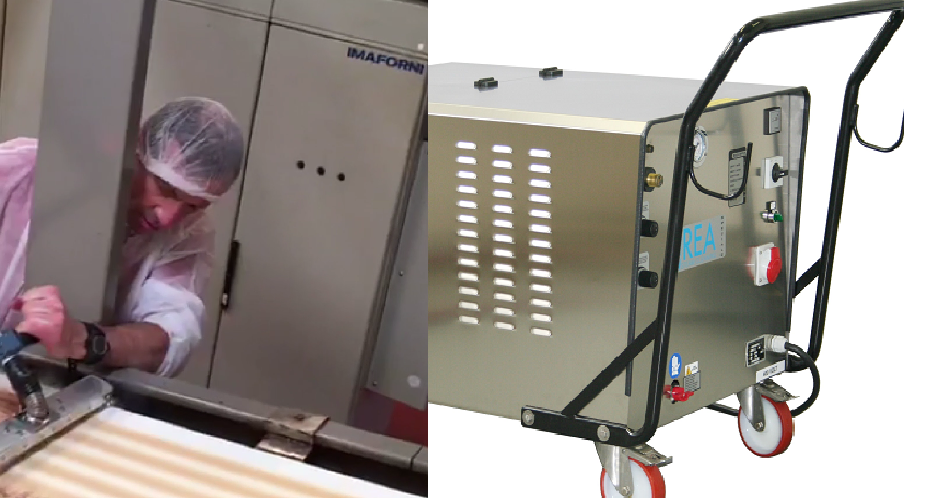

REA STEAM CLEANING develops and manufactures steam generators and conveyor belt cleaners for the food processing industry, which have been used for more than 30 years by all major companies for cleaning and sanitisation of equipment and production lines, both during and after processes.

We produce mobile steam generators, with and without vacuum, for fixed installations such as conveyors belts cleaners.

Our mobile steam generators range from 9kW (15kg of steam per hour) to 36kW (60kg per hour). Fixed installation units have no limit in steam output and can use existing steam networks within factories.

There are many benefits of using saturated steam technology in the food processing industry.

In our process, the steam hits the surface at a temperature of 160° . It destroys and eliminates most food plant pathogens (E.coli, listeria, salmonella, clostridia botulinum, campylobacter, bacilius cereus, clostridium perfugnens, staphylococcus aureus), including those in hard-to-reach locations and within biofilms.

Use of high temperatures eliminates the chance of bacteria developing resistance to chemicals. In addition, heat cause oils and greases to melt, making them easy to remove from equipment. Heated surfaces dry quickly, leaving them ready for use.

They are also safe for users, with the low moisture content eliminating any burning or scalding hazards.

Typically, the cleaning of equipment in food industry is a multi-step process that involves pre-rinse, wash with detergent, rinse to remove detergent residues, treat with sanitising agents and final rinse. With our products, the saturated steam allows for the completion of this this cycle in one step.

In most of cases, the high temperature eliminates the need for chemicals, so drastically reduces the associated risks and costs. The ability to use steam and water without chemicals assists organic producers in maintaining sanitation standards.

The process is low in moisture, with saturated steam containing only 6% moisture. Steam generators use only 13l- 52l of water (depending on models) as opposed to 700l-1,200l for pressure washing . No unclean water is left on the floor or sprayed around and areas without water drain can be easily cleaned.

Water consumption and wastewater are reduced by up to 95%, creating savings in costs for supply and disposal of water.

Low moisture does not cause any increase in humidity in a facility that could create condensation and food safety problems.

Pressure is low at 10bar, compared with 80bar and greater for pressure washers; this allows it to be used on and around electric components controls without the danger of causing a short-circuit or damaging components, so there is no need to mask off or bag equipment prior to cleaning. Bearings, seals, motors, sensors are also protected.

Minimal broadcast of soils and moisture compared with pressure washing allows steam cleaning to be used on equipment while production continues on alternative lines, increasing the speed of cleanup and decreasing the chance of cross-contamination. For powders and dry ingredients, the low-pressure combined with moisture in the steam causes them to solidify and fall to the ground from a very short distance, simplifying cleanup.

The addition of water and detergent is controlled from the handle. Adding water ensures proteins are removed from the surface and not baked on. Water assists in moving soils more quickly, speeding-up cleaning. If necessary, a very small quantity of detergent can be used to quicken cleaning and improve results. We have a full range of detergents that are compliant with HACCP regulations.

A full range of cleaning accessories is available, with short and long steam lances, brushes, wipers, suction brushes, suction nozzles and floor wipers with suction.

Fitted with a belt conveyor steam cleaner, production line disinfection is continuous, limiting downtime and ensuring cleaning is optimised.

REA STEAM CLEANING has developed a full line of automatic belt cleaners, fixed and mobile, without any limit in width, for the smooth, modular cleaning of mesh belts of any material, including plastic, steel wires and flat steel.

With our mobile belt convenor, cleaners are coupled with a 9kW steam generator and a simple vacuum, which is moved across the belt to cover the width.

Rosenqvists Food Technologies has extensive knowledge of the potato as a raw material and how to design an effective process.

REA STEAM CLEANING presents a detergent-free smooth belt automatic steam cleaner for the food processing industry.

A steam generator feeds a nozzle which, thanks to the steam, rotates very quickly above the belt.

The smooth belts automatic steam cleaner is detergent free and Haccp-compliant.

SATURNO COMPACT 3KW is an industrial-saturated steam generator used for sanitising and disinfection in the industrial, agri-food, transport and community sectors.

SATURNO COMPACT 3KW VAC is an industrial-saturated steam generator with integrated suction to be used for degreasing, sanitising and disinfection in the industrial, agri-food, transport and community sectors.

SATURNO SUPER is a heavy-duty professional saturated steam 9kW generator aimed for industrial, food processing, collectivities cleaning, degreasing, sanitising and disinfecting.

SATURNO SPECIAL 2 is a heavy-duty professional saturated steam 18 kW generator aimed for industrial, food processing, collectivities cleaning, degreasing, sanitising and disinfecting.