Foodservice Plant Cuts Costs and Equipment Downtime while Increasing Productivity by 80%

The plant achieved consistent sanitation standards, cut costs, improved efficiencies in multiple areas and improved worker safety by utilising dry ice blasting.

Simplify cooling and cleaning operations with dry ice, which provides a safe, residue-free and enhanced cooling and cleaning solution.

You have successfully submitted your enquiry. Someone from our company will respond ASAP

Cold Jet® is the world leader in developing innovative, environmentally sustainable dry ice production equipment and dry ice cleaning solutions.

Our two distinct lines of business focus on the use of dry ice. We provide systems for the production, metering and packaging of dry ice. These systems enable the consistent production of a controlled range of dry ice products for food transportation, cold chain management and batch cooling.

Secondly, we manufacture environmental cleaning, surface preparation and parts finishing systems for global manufacturing industries. These systems use particles of dry ice as a blasting medium. Customers are using our technology-based solutions to replace outdated processes that are inefficient and harmful to health, safety and the environment.

Cold Jet is headquartered in Loveland, Ohio, US; with international operations in Europe, Asia, Canada and Mexico.

Cold Jet allows companies to use dry ice to maintain critical temperatures in food processing applications.

Dry ice is used in many types of food processing facilities, including bakeries, to control temperature, impede bacteria growth and reduce spoilage. Dry ice is a food-grade media and is approved by the US Food and Drug Administration (FDA), US Department of Agriculture (USDA) and Environmental Protection Agency (EPA) for use around food.

Benefits for meat processing, commercial bakeries, winemaking (cryomaceration) include:

On-site dry ice production is critical for delivering perishable goods that keep customers happy and healthy.

On-site dry ice production allows food home delivery services and third-party logistics (3PL) companies to take control of their cold chain by providing just-in-time dry ice production solutions that eliminate the impact of supplier shortages.

Dry ice for food home delivery maintains critical temperatures during the transport of perishable goods, helping to reduce spoilage by mitigating the risk of thawing and leaking items.

The unique characteristics of dry ice make it a more efficient and cost-effective solution than traditional cooling methods such as gel packs or refrigerated trucks.

Benefits for food home delivery, third-party logistics (3PL) include:

Food processing and packaging equipment accumulates grease, carbonised residue, seasonings, proteins, harmful bacteria, biofilms, adhesives, and many other contaminants that traditionally take significant time to clean.

Dry ice blasting for the food industry provides an in-situ cleaning solution that is non-abrasive, sustainable, does not use water or chemicals and does not produce secondary waste. Cold Jet allows clients to experience a cleaner clean with a fraction of the waste.

Dry ice blasting thoroughly cleans contamination from process and production equipment in-situ, without water or chemicals, and even while the equipment is still running.

Benefits of using dry ice to clean processing and packaging equipment include:

The plant achieved consistent sanitation standards, cut costs, improved efficiencies in multiple areas and improved worker safety by utilising dry ice blasting.

The safe, moisture-free dry ice cleaning eliminates any set-up, including wrapping electrical equipment.

The unique properties of dry ice offer a water-free, chemical-free clean that significantly reduces downtime and eliminates repetitive motion and rework.

Like water ice, dry ice (consisting of recycled carbon dioxide in solid form) can be shaped as required by the application.

Dry Ice - The Best Cooling Medium for Perishable Goods.

Cold Jet is the trusted solution partner for all industries and applications requiring dry ice slices, blocks, pellets or nuggets.

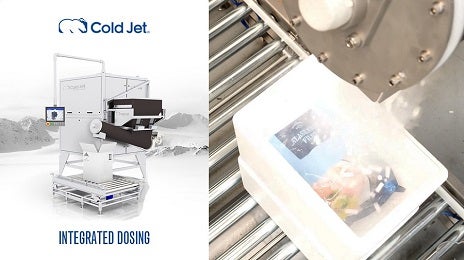

Take control of your dry ice supply and begin producing dry ice just-in-time with the Cold Jet integrated dry ice dosing system.

Versatile dry ice blasting machine for cleaning any food processing and packaging equipment without chemicals or water.