Continuous Processing of Ready-To-Drink Tea and Coffee Beverages

The convenience and availability of Ready To Drink (RTD) tea and coffee is consistent with the changing lifestyle of consumers worldwide.

You have successfully submitted your enquiry. Someone from our company will respond ASAP

Flavourtech provides companies worldwide with aroma recovery, evaporation and extraction technology, which allows clients to differentiate their products. Its high-quality processes help meet consumer taste preferences naturally, easily and with maximum flexibility.

Using low temperatures and short processing times, Flavourtech’s technologies help ensure natural flavours and active ingredients are protected while high-quality products are produced. The company’s turnkey solutions can also lead to streamlined processes, lower costs of production and higher market share.

With more than 90 installations in the coffee industry, Flavourtech’s Spinning Cone Column (SCC) is the ‘gold standard’ for aroma recovery during the production of instant coffee. It is also used in the tea industry to capture distinctive varietal tastes, assisting producers in product differentiation.

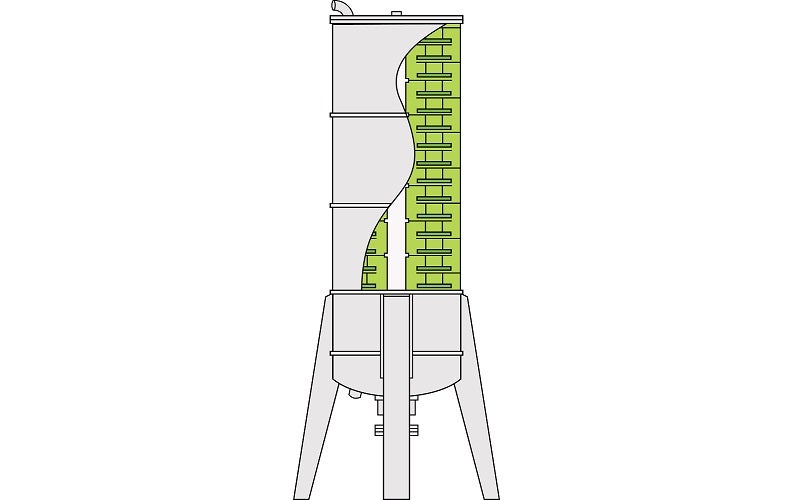

Flavourtech has built on this success and now offers turnkey solutions, such as the Integrated Extraction System (IES), which lends itself to both ready-to-drink (RTD) and instant tea and coffee products. The automated system both efficiently and cost-effectively separates volatile aroma and flavour compounds from slurries of tea and coffee, while producing a high-quality extract, which may then be concentrated or dried.

Flavourtech’s solutions can be applied throughout the whole coffee or tea production chain, from milling to powder formation. The company’s Rotating Disc Column (RDC) may now also be integrated into an IES line, offering soluble coffee manufacturers a revolutionary alternative to traditional multi-cell extraction systems. Built to customer’s requirements, the IES is compact, flexible, easy-to-use and offers advantages such as process and energy savings, maximum flavour retention and high-quality end products.

Flavourtech’s SCC is used by companies worldwide for the gentle extraction of natural flavours from fruits and vegetables. The SCC’s aroma recovery technologies are capable of processing materials containing a high proportion of suspended solids such as slurries and purees. This capability allows the SCC to extract natural essences and oils prior to damaging thermal processes such as juicing.

The SCC is also used to recover natural flavours from various streams of fruit juice production, including pulp and evaporator condensates. These flavours may then be added back to the final juice product or sold as separate revenue streams for flavouring other products.

Flavourtech’s Centritherm® evaporator technology is used for the concentration of high-value or viscous juice products for maximum flavour and colour. The high-vacuum model removes agricultural residues from citrus oils commonly used in beverage flavouring.

Flavourtech’s SCC was originally developed for desulphiting single strength grape juice in the wine industry. Today, wine applications include alcohol adjustment by 1% or 2% to reduce the warmth of high-alcohol wines and the removal of alcohol for the production of reduced or zero alcohol wines, as well as the recovery of flavours from grape juice, wine and waste streams.

The SCC helps retain delicate flavours without damaging characteristic top-notes. Low-temperatures allow the amount of alcohol removed to be controlled and flavour to be protected.

In the beer industry, the SCC has been used for a number of years to produce Low Alcohol Beer (LAB) containing aroma from the original feed material. In conjunction with the SCC, Flavourtech’s new Resin Adsorbing Column (RAC) is now facilitating the production of No Alcohol Beer (NAB) that incorporates aroma recovered from the original full strength beer. This allows for a more flavoursome zero alcohol beverage while avoiding the requirement to add and potentially declare external flavours on a product label.

Finally, with the growing popularity of Kombucha beverages, the SCC is gaining recognition as the preferred method for removing alcohol generated during the Kombucha fermentation process. This enables manufacturers to comply with alcohol content legislation while preserving the valuable probiotic component of the Kombucha.

Flavourtech’s Centritherm evaporator is an ideal unit for the concentration of extracts containing bio-active compounds. It allows for one second product contact time on the heating surface at low operating temperatures of approximately 40°C to 50°C. This means the evaporator helps protect valuable products and it has been specifically designed to meet various pharmaceutical industry requirements.

Viscous products can also be concentrated with the Centhitherm evaporator, with a low hold-up volume resulting in less waste. This flexible machine has a clean-in-place (CIP) functionality and can operate at various temperatures and flow-rates for processing multiple products.

Flavourtech can assist dairy companies’ processing requirements in two ways:

Flavourtech’s customers include market-leading domestic and multinational companies. Its technologies allow clients to differentiate the flavour and scent of products while providing flexibility and quality.

The convenience and availability of Ready To Drink (RTD) tea and coffee is consistent with the changing lifestyle of consumers worldwide.

Flavourtech's manufacturing technology is known for its ability to recover superior flavours and extracts, while maintaining the natural properties of the raw material.

Established in 1987, Flavourtech is a global technology manufacturer specialising in aroma recovery, extraction, dealcoholisation and evaporation solutions for the food, beverage and pharmaceutical industries.

Fruit processors around the world are looking at techniques to differentiate their final product in today’s competitive market.

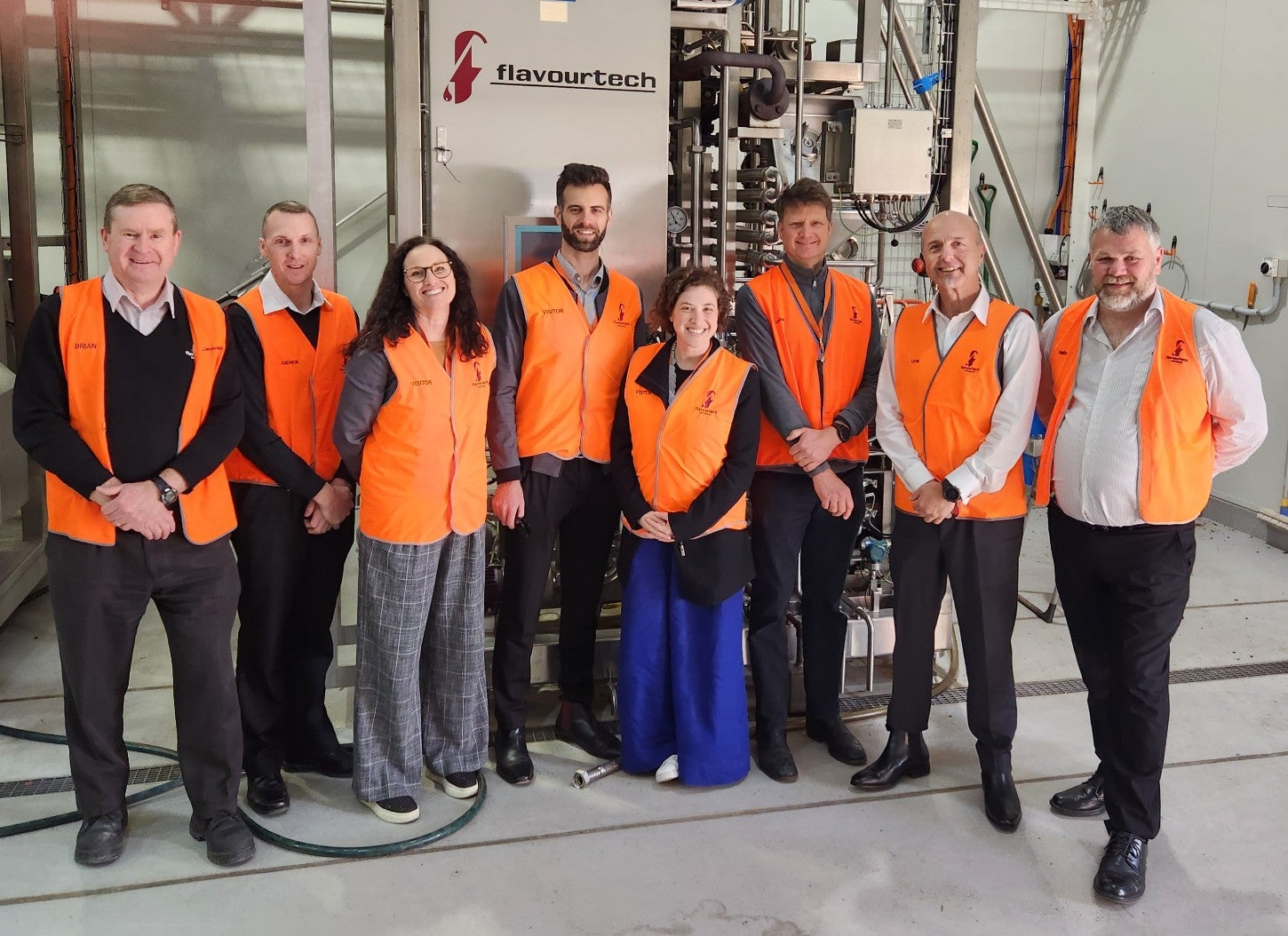

Australian manufacturer of unique processing technologies, Flavourtech, officially opened its new headquarters in Griffith NSW on Tuesday 9th December 2025.

Plus Ultra III was officially opened by Peter Ploegsma (WUR), Michel Leemhuis (Kadans), and Wageningen's Mayor, Floor Vermeulen on the 12 of November in Wageningen.

Australian process technology manufacturer, Flavourtech has once again been named Regional Exporter of the Year at the Premier’s NSW Export Awards.

Announced at a Gala Ceremony at Piccolo Family Farm, these awards recognise excellence in business leadership, innovation, sustainability and employment.

Australian manufacturer of unique processing solutions, Flavourtech, will be exhibiting at Drinktec in Munich from 15 to 19 of September.

Flavourtech’s Global Sales Manager Paul Ahn will be presenting NoLo - The Next Generation in Low Temperature Vacuum Distillation from 11:30 am on Wednesday 23 July.

Located in the regional NSW town of Griffith, Flavourtech is a global technology manufacturer specialising in dealcoholisation, aroma recovery, extraction and evaporation solutions for the food, beverage and pharmaceutical industries.

Australian technology manufacturer Flavourtech is proud to provide university students the opportunity to gain practical work experience through their Work Placement Program. The programme offers students a mix of short or long-term placement periods in the fields of Engineering and Project Management.

Flavourtech is incredibly proud to be awarded Regional Exporter of the Year in the 2024 Premier’s NSW Export Awards.

Australian food & beverage technology manufacturer, Flavourtech was honoured to be recently featured on the Australian Broadcasting Corporation's Landline program.

Construction of a multi-tenant building, Plus Ultra III, officially commenced yesterday at Wageningen University in the Netherlands. On completion, Australian technology manufacturer Flavourtech will be the first tenant in Kadans Science Partners’ new building for companies from the food, feed & biobased sectors.

The World Tea & Coffee Expo (WTCE) will be held next week in India with Australian technology manufacturer, Flavourtech, presenting on Day 2 of the show.

Flavourtech was honoured to host a delegation from Australia’s Department of Foreign Affairs and Trade (DFAT) last month at their Australian headquarters.

Flavourtech is proud to be featured as a success story on the Australian Trade and Investment Commission (Austrade) website.

Judging of the Mid-Low-No Alcohol Wine Awards (MLNA) has taken place and Gold Sponsors, Flavourtech, are only too happy to announce the Overall Judges’ Wine of Show as Not Guilty Rosé NV from their long-standing customer, Australian Vintage Limited.

Flavourtech Pty Ltd and partners have been granted Australian Government funding from the CRC-P programme to further investigate no and low-alcohol wines.

Flavourtech is incredibly proud to be awarded Regional Exporter of the Year in the 2022 Premier’s NSW Export Awards.

Aquaporin’s natural concentration technology is a revolutionary method of concentrating natural aromas without using traditional heat and pressure processes.

Ideal for use in the laboratory, pilot plant or small production runs, the new SCC100 is now able to dealcoholise wine.

Flavourtech is proud to share the success of their New Zealand customer, Giesen Group, and their range of zero alcohol wines.

Australian technology manufacturer, Flavourtech Pty Ltd, was last week presented with Austrade’s National Recognition Award for Resilience, Ingenuity and Courage.

For over 60 years, FreshFood Services have been transforming premium coffee beans into exquisite coffee, producing many of Australia’s leading brands, including The House of Robert Timms, Bushells Coffee, Picco, Café-Bar and Europa.

Flavourtech is a world leader in the development, design and manufacture of thin film, spinning cone technologies for aroma recovery, dealcoholisation, extraction and concentration.

In 2021, Flavourtech has acknowledged its 30 year partnership with long-term customer, Australian Vintage Limited (AVL).

Regional technology manufacturer Flavourtech Pty Ltd was one of 15 businesses to be recognised at the 2020 Premier’s NSW Resilient Exporter Awards luncheon in Sydney last week.

Leaders in the field of natural fruit and vegetable flavours, Döhler has recently chosen to partner with Flavourtech in order to continue its expansion in this area and provide its consumers with the very best of nature.

Flavourtech is proud to announce the SCC100, which is the newest member of the Spinning Cone Column (SCC) family.

With international travel coming to a standstill during the Covid-19 pandemic, Flavourtech is continuing to support its global customers by conducting plant commissioning and end-user training sessions remotely.

The new Flavourtech Resin Adsorbing Column (RAC) allows manufacturers of ‘0.0’% abv wine and beer-based beverages to recover and return aroma derived from the original product without any measureable increase in the final alcohol content.

Australian process technology manufacturer Flavourtech has recently appointed Deska-Imex as its distributor in Russia and the Commonwealth of Independent States (CIS) countries of Ukraine and Kazakhstan.

Flavourtech is proud to announce that it has been awarded the 56th Australian Export Award for Manufacturing.

Flavourtech is extremely proud to be awarded the 2018 Premier’s NSW Export Award in Manufacturing for the second year in a row.

Flavourtech has won the Outstanding Employer of Choice, Excellence in Business and Excellence in Export awards at the recent Murray Riverina Regional Business Awards.

Australian process technology manufacturer Flavourtech has recently appointed Maquinaria Jersa as its new agent in Mexico.

Flavourtech has announced it will attend Achema in Frankfurt, Germany, to showcase its innovative processing technologies.

Flavourtech has announced that it has been awarded the NSW Excellence in Business award at the recent NSW Business Chamber’s State Business Awards.

Flavourtech has announced its success at the NSW Business Chamber Awards that were held at the Albury Entertainment Centre.

Flavourtech has announced it will attend Drinktec in Munich to showcase its innovative processing technologies.

Based in Griffith, NSW, Australia, Flavourtech manufactures high technology process equipment for the food and beverage industries.

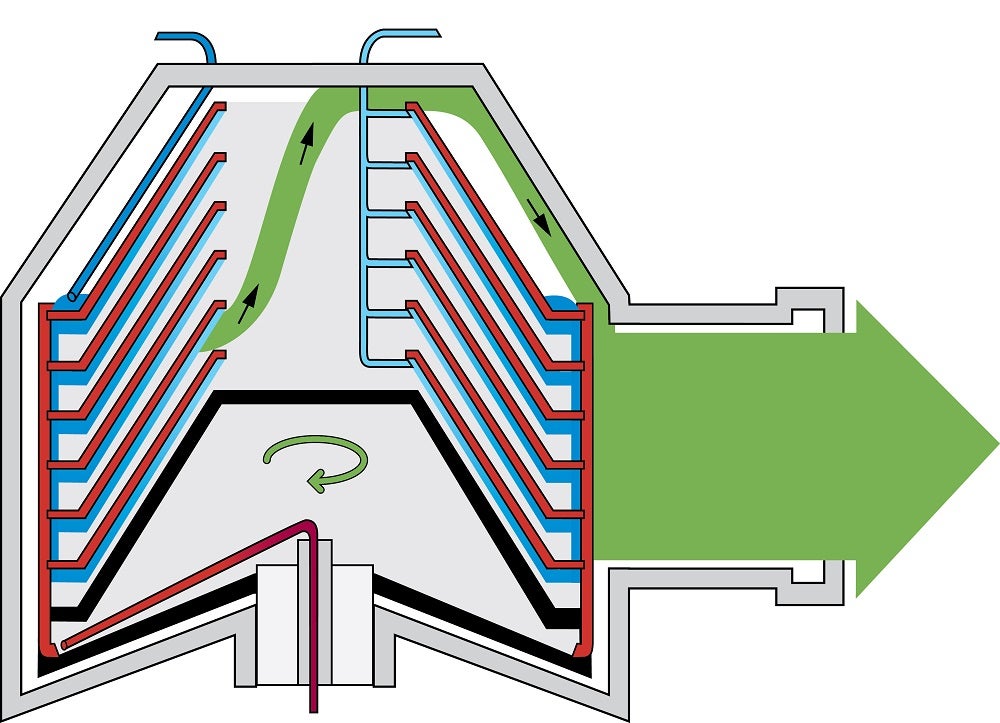

Flavourtech's Spinning Cone Column (SCC) uses steam stripping to extract and recover volatile compounds in vacuum conditions.

Flavourtech's Centritherm® is a centrifugal, thin-film evaporator suitable for concentrating heat-sensitive, valuable, or viscous products.

Flavourtech's Integrated Extraction System (IES) is a continuous, automated processing line, which produces premium aromas, concentrates, and extracts for instant and ready-to-drink (RTD) tea and coffee products.

The Flavourtech Rotating Disc Column (RDC) is a continuous contacting device for the food and beverage industry.

The Flavourtech Resin Adsorbing Column (RAC) allows producers of ‘0.0’ % abv beverages, such as wine, beer and cider, to recover and add back aroma derived from the original product.

This video introduces the products and services offered by beverage processing company Flavourtech.

This video offers an overview of Aquaporin and Flavourtech's new ESSENCE go solution.