Food brands are keen to expand their assortment in the alternative proteins and plant-based sector, which is still growing despite the challenging global economy and stubborn inflation which has pushed up the basic cost of living around the world.

Market intelligence firm GlobalData projects growth in the alternative dairy and meat sector over at least the next few years, as consumers continue to switch to more climate-friendly vegetarian, vegan and flexitarian diets. GlobalData analysis projects a 7% compound annual growth rate (CAGR) in the meat substitute segment between 2023 and 2028, down from 9.7% CAGR in the period between 2018 and 2023, but still more than enough for brands to take notice.

Unique opportunity

GEA, a leading provider of machines, know-how and full process lines to the global food and beverage industry, believes these new foods represent a unique opportunity to set the world’s food system on a more sustainable, environmentally sound path.

“Alternative proteins hold the promise of helping feed a growing population using fewer resources,” says head of the GEA Bakel Technology Centre Sanne Hermsen. But that doesn’t mean the path to success in this fast-growing food segment is straightforward or guaranteed, especially as the category gets increasingly saturated.

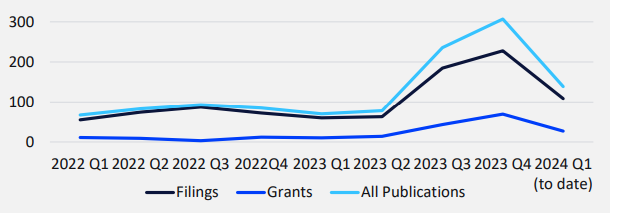

A jump in the patent pipeline in 2023, as is evidenced by GlobalData, which tracks patent activity from more than 100 authorities around the world, shows that companies are under pressure to invest in product formulations. Reducing risk in the innovation process is critical to keep costs under control and to maximise ROI in a challenging business environment.

This is what GEA’s technology centres aim to achieve for their customers.

In its Bakel Technology Centre in the Netherlands, brands can perform preparation, marination and processing trials before going to full scale production. Just-Food sat down for an exclusive Q&A with Hermsen to find out more about how the food technologists at the Bakel Technology Centre work with food manufacturers and discovers that there can be huge benefits to playing with your food.

Just-Food: Can you tell us about the Technology Centre at Bakel, and what you do there?

Sanne Hermsen (SH): I’m the technology centre manager, and I’ve been at Bakel for two years now, after working previously as a product developer for vegan/vegetarian products. At GEA we say that the Tech Centre is a safe area for our customers. They can come here and do whatever they want; they can test the equipment and play with the settings. We can change full line set-ups without any time or production pressures. We are really using it to show the customer the endless possibilities there may be for their product. In 2023, we had 235 different trials from customers from more than 40 countries.

Source: GlobalData Patent Analytics

How has processing developed over the past five years, and how do plant-based foods fit into the picture?

SH: We see that the biggest companies are getting bigger and bigger, and the smaller ones are at risk of being left behind. It’s all about production efficiency, you want to use your factory in the best functional way. Then, in combination with that, is sustainability. In the TC (Technology Centre) we are working to help our clients reduce costs and show them how they can save energy, save water, reuse ingredients. Sustainability is really the key.

In terms of food trends, we know that the market for plant-based products in the poultry industry has seen a shift over the past few years, with a significant increase in trials. Between 2019 and 2021, we saw plant-based trials jump from 10% to almost 30%. In 2021, more vegan and vegetarian-based products were tested in the TC than poultry, which had historically been the dominant product group for testing.

Now, the market is stabilising but GEA is seeing an increase in trials using different configurations of hybrid products in which animal products are combined with alternative raw materials, such as vegetables. These trials are making up about 40% of all tests at GEA right- a powerful signal of the potential of new food.

One of the major advantages of GEA machinery is that you can quickly switch from the production of animal-based products to plant-based products without major adjustments to settings. This is one prominent factor we believe behind the recent sales rise of the CutMaster, which is used to produce fat emulsions, and the ScanMidi for hydrating textured proteins. We are also seeing manufacturers be more considerate of the health effects of the ingredients they use. It has become more important for them to access a higher protein and fibre percentage and reduce salt and saturated fat in formulations in addition to use ingredients with a lower CO2 food print.

The reduction in, for example, saturated fat can be seen in the trend of replacing coconut fat for sunflower and rapeseed oil since coconut fat contains a relatively large amount of saturated fat.

Can you explain in more detail how the TC works? What do you provide to your customers and what do they get out of it?

SH: It’s really about being a playground for the customers, so that they can learn, validate, experiment and innovate. Not only for new products, but also for existing products that they may want to upgrade. They can run small tests on one piece of equipment, but we can also do a full-scale line solution trial. Within the technology centre in Bakel, customers can test with complete confidentiality – for recipe formation, equipment settings and line setups.

The people who work in the Technology Centre in Bakel all have extensive knowledge of many different applications, not only for meat, but also fish, vegetables, ready meals, pet food and new food.

Credit: GEA

GEA is not an ingredient supplier, but we have vast knowledge of ingredients and experience in product development for the food industry. We can help with machine settings and even recipe adjustments. By understanding and addressing our customer concerns, we can provide good products and optimised line setups to meet the needs of the consumer.

Do you have any good examples of challenges and solutions the TC delivered for your customers?

SH: A customer which produces vegan chicken products came to the TC considering investing in a new mixing machine. The production time of the vegan chicken mix was two-and-a-half hours, which we were able to reduce to 30 minutes. The trial day started with the production of the vegan chicken mass as the customer normally produces the mass. After this, my team and I began to optimise mass production using the GEA ProMix, Powergrind, CutMaster using our experience as food technologists.

At the end of the process, the final product that rolled off our production line was compared with the product they’d produced on their own and the customer was very impressed because there was no significant difference in structure, taste and appearance – but a huge difference in speed of production.

Can you tell us about key developments and achievements from the TC?

SH: Recently, trials have focused on texture and nutrient content, particularly for smaller companies. Scaling up these developments is crucial, as even when customers are large, the focus is on the scale of their operations, efficiency and line solutions. This is where our strength lies.

For example, the production of vegan products can be challenging due to the variation in ingredients, structures and required temperatures, but through our extensive application knowledge we can help the customers in every possible way.

Credit: GEA

How do you see trends in plant-based food unfolding in 2025?

SH: We are seeing a movement towards improved nutritious value of the plant-based product (low slat, low saturated fat, low calorie, high protein and fibre content). There is also a shift towards hybrid products.

Sustainability will remain a hot topic. In the future we will collaborate with other divisions at GEA active in new food, like those innovating with bioreactors capacity to scale up production of cultured meat, precision fermentation and mycoproteins so that we continue to play a crucial role as an enabler, helping this new field to grow faster and bring new ideas to reality.

To sum up – what would you say are the key benefits of this Tech Centre?

SH: We can help the industry by introducing new processes and comparing them to traditional methods. We believe this can change mindsets and help our customers develop. Feedback indicates they believe our approach has made a significant difference.

Customers are coming here to use their imagination and test before they invest. We can also offer remote testing if travelling is difficult. We have the time, we have the space, we have the room, we have the knowledge.

Read more about the major factors that contribute to the success of plant-based food in GEA’s free whitepaper below.