Working alongside chocolatiers in the food industry, researchers at ETH Zurich say they have identified a healthier and more sustainable way of creating chocolate, using more of the cocoa pod. According to Kim Mishra, the main author of a study published in the journal Nature Food, the adoption of the method could help to manage rapidly rising cocoa prices.

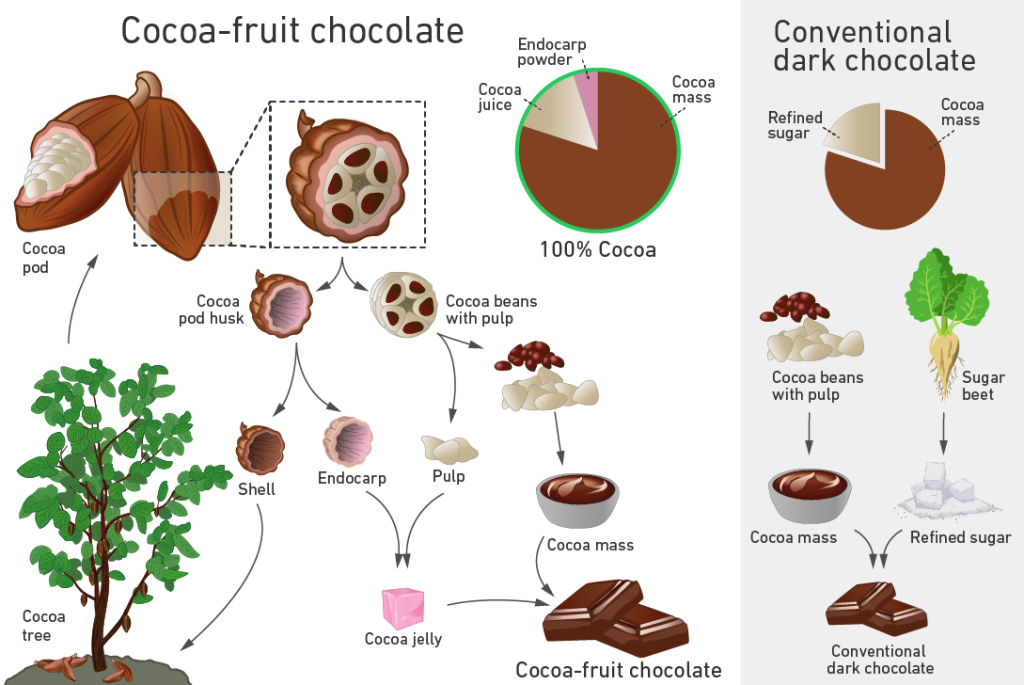

While traditional chocolate uses only the cocoa beans and discards the pulp and endocarp, the new recipe focuses on the potential of the entire cocoa pod.

Discover B2B Marketing That Performs

Combine business intelligence and editorial excellence to reach engaged professionals across 36 leading media platforms.

Speaking to Just Food, Mishra explains: “If you imagine the cocoa fruit, you have to think of it like a melon or a pumpkin. Chocolate is made by harvesting the seeds, which make up only 25% of the fruit, which are processed into chocolate; the pulp and the husk you basically don’t utilise. What we did is that we took the juice from the pulp – which is quite sweet – and we ground and dried the husk into a powder.

“If you combine these two elements, the sweet juice and this fibre-rich powder, you make a gel – it’s like a sweet gel or a jam. You can add this to your cocoa mass that you make out of the beans, and that way you have sweet chocolate, just using the natural components of the fruit.”

The gel is used to replace traditional powdered sugar in dark chocolate, offering what the researchers say is a healthier alternative through the increased fibre content (around 15g per 100g of chocolate, versus traditional chocolate’s 12g). Proponents say further benefits are offered through the reduction of saturated fat, with ETH Zurich’s chocolate containing 23g, whereas traditional chocolate contains approximately 33g. This represents a 30% decrease in saturated fat and a 20% increase in fibre.

The pressure industry is facing from cocoa prices

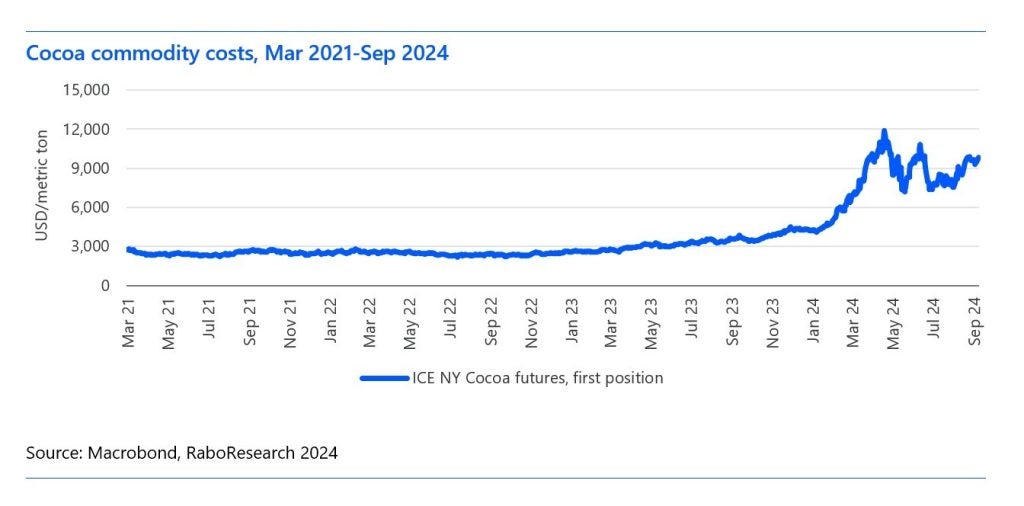

A drop in the global supply of cocoa, driven by disease and climate change in the two biggest cocoa-supplying countries – Cote d’Ivoire and Ghana – saw cocoa prices reach record highs this year. The most recent estimates by the International Cocoa Organization expect a 14.2% reduction in global production in the 2023-24 season compared to the previous year. This equates to a shortage of around 462,000 tonnes and the lowest cocoa stocks in 22 years.

US Tariffs are shifting - will you react or anticipate?

Don’t let policy changes catch you off guard. Stay proactive with real-time data and expert analysis.

By GlobalDataAs a result, prices reached almost $12,000/tonne in the first half of 2024. While pressures have eased since then, the industry has been left scrambling to find a long-term solution to the developing climate issues. In the short term, producers have absorbed some costs, but consumers have already seen both inflated prices and ‘shrinkflated’ products on the shelves.

Looking forward, Julia Buech, senior analyst in consumer foods at Netherlands-based financial services group Rabobank, says: “The full force of the cocoa crisis is yet to be felt on supermarket shelves. Due to the lag in the supply chain and existing contracts, the steepest price hikes are anticipated in the second half of 2024 and into 2025.”

This is expected to lead to higher prices for consumers, particularly for dark chocolate products, which contain higher cocoa content.

It’s a problem the new chocolate-making method has the potential to solve, the researchers say. “By harvesting more of the fruit, it is possible to counteract the large increase in cocoa prices because you can have more cocoa in your chocolate without using the beans,” Mishra says.

More cocoa usually equates to more expensive (and higher quality) chocolate. While different recipes consider different quantities of cocoa to be the ‘right’ amount, dark chocolate is usually accepted to be made up of around 70% cocoa.

An EU directive issued in 2000 states dark chocolate sold in the bloc must contain a minimum of 18% cocoa butter, 35% total dry cocoa solids and 14% dry non-fat cocoa solids. For milk chocolate, it directs that products must contain a minimum of 25% total dry cocoa solids and 2.5% dry non-fat cocoa solids.

Mishra acknowledges the new ingredient generates some sticky questions in terms of quantifying cocoa in a product, noting: “Technically, it’s all cocoa, right? It’s all cocoa fruit. So, is this product now 100% cocoa chocolate?”

If the new product is considered to be 100% cocoa, it could see prices drop, as higher cocoa percentages are achieved from fewer cocoa beans, making chocolate production processes more efficient. It could also open the door to new earning opportunities for struggling cocoa farmers.

What the new chocolate-making method could mean for cocoa farmers

The recipe for the newly designed chocolate was designed in collaboration with sustainable-cocoa producer Koa and Swiss chocolate manufacturer Felchlin.

Speaking to Just Food, Anian Schreiber, co-founder and managing director at Koa, explains: “The continuous struggle of smallholder farmers to make ends meet, in combination with increasing climate change effects on the cocoa trees, is one of the major root causes for the global cocoa shortage and soaring cocoa bean prices in the past year.”

Most cocoa farming takes place on small farms, and the personal difficulties of struggling farmers become part of a cyclical problem. Despite lower supplies driving up prices, cocoa farmers earn only an average of 6% of the final chocolate price, according to The Fairtrade Foundation.

Tony’s Chocolonely is reputed for its work on ethical chocolate in line with its Open Chain five sourcing principles. These include charging a ‘Tony’s premium’, paid directly to cocoa cooperatives, and committing to five-year projects with cooperatives to facilitate investments. The company has called for change across the industry, with its most recent campaign inviting seven famous ‘Tonys’ (including the likes of Tony Hawk, Sir Anthony Hopkins and Antoni Porowski) to join in its message against exploitation.

Speaking to Just Food, Belinda Borck, global public policy coordinator at Tony’s Chocolonely, says: “Unfortunately, high prices on the cocoa trading market don’t necessarily mean higher prices paid to cocoa farmers. There are devastating consequences like 1.5 million children still working illegally on cocoa farms.”

“Tony’s know they can’t change the whole industry alone, so they campaign for governments to change legislation, for retailers to change how they source cocoa, for consumers to purchase more consciously.”

Tony’s Chocolonely’s concerns are echoed by Schreiber at Koa. “The cocoa industry continues to struggle with systemic market failures leading to an unfair value chain where farmers are disadvantaged, often continuing to live below the poverty line, due to volatile prices and an unequal distribution of profits, particularly in west Africa,” she says. “Child labour remains a widespread issue, driven by the economic hardships faced by farming families.”

A more efficient chocolate sector could resolve some of the ethical issues embedded in the current cocoa trade. According to Mishra, the developers hope that the new chocolate will offer “benefits for the farmers, which have more diverse income due to the splitting of one fruit into three value streams”.

From concept to shelf

A chocolate product which switches out refined sugar for the cocoa pod’s naturally sweet pulp isn’t an entirely new idea. In 2019, Nestlé released a KitKat Cacoa Fruit chocolate in Japan, which followed a similar logic: the product was sweetened exclusively with pulp, extracted using the brand’s in-house method.

Crucially, Nestlé’s product did not create a “sweet gel or a jam” from the pulp, as ETH Zurich’s work does. It also did not seek to utilise the endocarp. Nevertheless, it promised similarly beneficial results for cocoa prices and farmers’ revenue.

Nestlé scaled up its offering in 2021, launching a dark chocolate under its Les Recettes de L’Atelier brand. The product – Incoa – was made available in a selection of markets in Europe; however, it was abandoned within two years.

Speaking to Just Food, a Nestlé spokesperson explains “the launch was well received by the media and retailers due to the compelling and innovative sustainability-related story behind it.

“However, in the longer term, the range of whole cocoa fruit tablets did not create a sustainable business for Nestlé neither in Europe nor in Japan and therefore was discontinued globally by 2023.”

The challenge for the ETH Zurich team lies then in the marketability of its product, which Mishra explains will require a leap of faith from the sector.

“It always needs a rather daring implementation partner company who is willing to take the risk of launching such a product. Making a product is a costly thing as a food company. You have to you need developers, you need to create the line, you have to do everything. Taking that risk is a big step for a company but, I’m quite sure, based on the feedback I got from various institutions and companies, that there is interest around: who’s going to throw the first stone?”

It always needs a rather daring implementation partner company who is willing to take the risk of launching such a product.

Kim Mishra, Institute of Food, Nutrition and Health, ETH Zurich

Mishra is also confident the product is unique and will forge its own path in the market. He explains the process “didn’t happen overnight” but took between two and three years and was the dedicated research of three masters’ theses. The complications were specifically around the differing textures of the chocolate, depending on the quantity of gel extracted from the pulp.

Of the rationale behind the research, Schreiber says: “In a first step, we started by upcycling the often-overlooked pulp surrounding cocoa beans, which we turn into tasty ingredients, such as 100% natural juices, concentrate and flakes, to be used primarily in chocolate and drinks applications. Naturally, we started researching what other parts of the cocoa fruit could be utilised. In a working session with Prof. Erich Winddhab of ETH Zürich, we realised the techno-functional properties of the endocarp were quite promising, so we partnered up to initiate the research.”

To ensure the recipe was to a high standard, trained panellists from the Bern University of Applied Sciences taste-tested pieces of chocolate weighing 5g each. Different pieces had varying quantities of powdered sugar and cocoa gel, and each was tested in an attempt to “empirically determine” the recipe.

Describing the finished product, Mishra adds: “I think that the sweetness sensation [of the cocoa gel] has a very different way of manifesting in your mouth. Think of it the same way as when you take honey in your mouth versus taking a sugar cube. It’s a slower sweetness, with juice; the husk powder of cocoa has aromas of dried fruit, of lychee, of pineapples, so more fruity, with some acidity from the juice. I would say it’s a fruitier, more complex chocolate.”